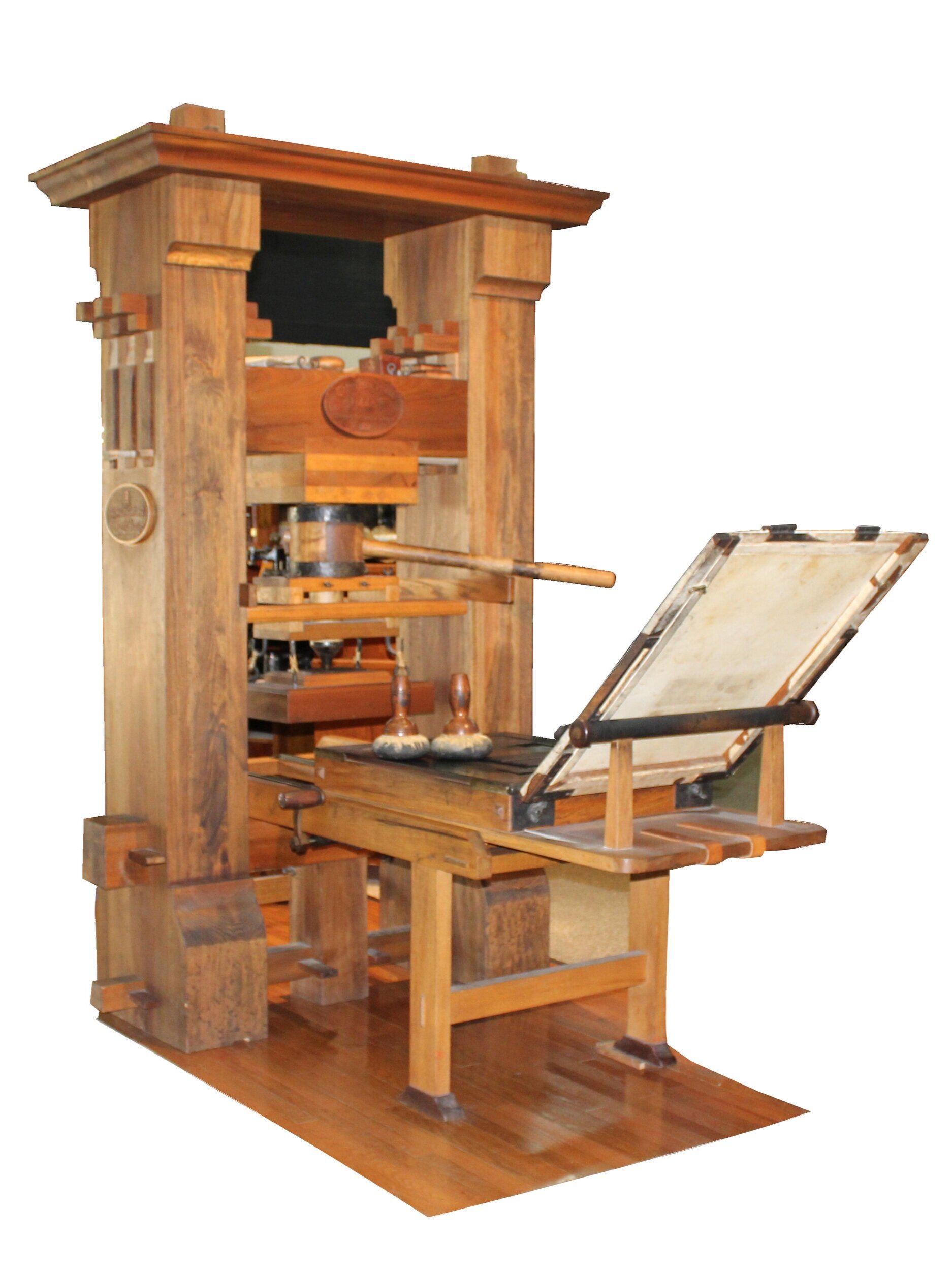

GUTENBERG PRESS

If you type “Printing Press” into Google, the first picture that comes up is of this very press. Johannes Gutenberg is known as the “Father of Printing” because he was the first to combine the use of molded movable metal type, a press, and printer’s ink.

Unfortunately, Gutenberg’s actual press, the very first printing press, has been lost to history. We know very little about the specifics of Gutenberg’s inventions and even less about the physical details of his original press. The earliest surviving press is from the mid-16th century and the earliest illustration of a press is the work “La Grant Danse Macabre,” which was made in 1499, nearly 50 years after Gutenberg invented the press. The scarce knowledge we have about Gutenberg is from contemporary court documents. In these records, his press is described as “a faster writing machine.” One assumption is that Gutenberg adapted the technology of a wine or olive oil press when he was designing his printing press. The technology of applying pressure with a screw and lever combination already existed, so it makes sense that he would borrow the idea for his own invention.

Our Gutenberg Press is a replica that was created specifically for the Museum in the 1990s. Its design is based on woodcuts from the 15th and 16th Century, such as the “Danse Macabre.” It is also very similar to a press that can be found at The Gutenberg Museum in Mainz, Germany. Museum Founder Ernie Lindner tediously, and somewhat secretly, took down the measurements of the press in Mainz during a visit in the 1960’s. From that information, drawings were made with the hope of someday constructing the press and adding it to the Lindner Collection of Antique Printing Machinery. In 1999 Ernie commissioned Steve Pratt of Pratt Press Works in Cove Fort, Utah to make the press. Ernie worked closely with Steve regarding design and measurement to make the most accurate version of the press as possible. Up until that point the troubling part of constructing the press, as Ernie mentioned, was cutting the thread of the screw located inside the press, and then cutting the corresponding nut which the screw turns inside. The screw would have been cut by hand with the threads at a pitch of 3-1/2 to the foot. Steve Pratt was able to solve this dilemma and build the press.

The Lindner Gutenberg measures 7 by 5 feet and is over 8 feet tall. It is made of ten different hardwoods:

1. Poplar – Cheeks, Cap, Winter, Platen

2. Ash – Platen, Cap

3. Hard Maple – Screw, Gallows Rod

4. Elm –Spacers under Winter

5. Black Locust – Lowest Wedges

6. Hickory – Nut, Coffin, Carriage, other

7. Birch – Dowels

8. Cherry – Chase, Coins

9. Walnut – Handle on Rounce, Feet

10. Oak – Tympan